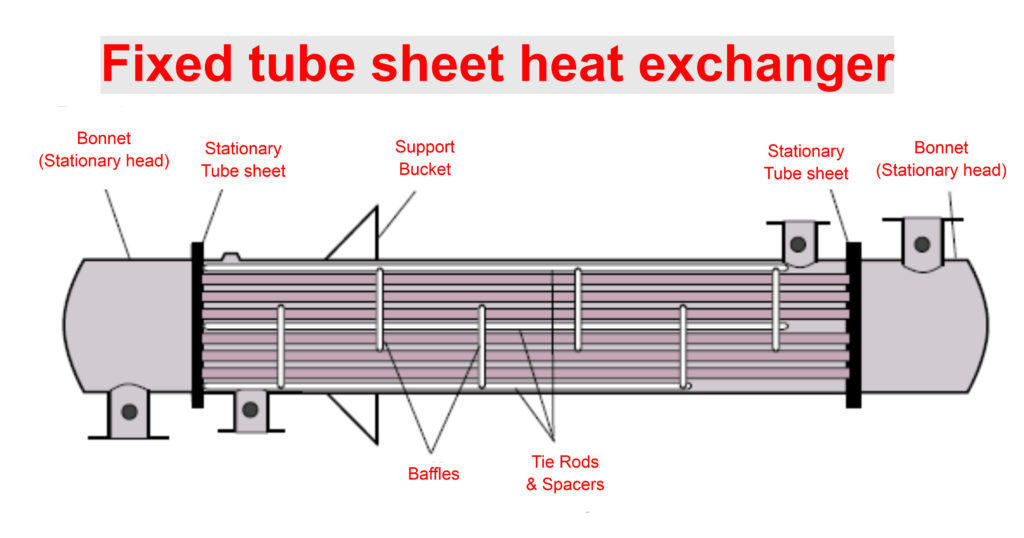

Fixed tube sheet heat exchanger

Fixed tube sheet heat exchanger

These are commonly used up to temperature difference of 90-95° C. Above these temperature differences problems of differential expansion arise. These are used when shell-side fluid is clean and non-fouling.

Advantages and Disadvantages of Fixed tube sheet heat exchanger

Advantages:

- It is simple in construction and economical.

- Gasket joints are minimum.

- Shell is welded to tube sheet on both sides, so leakage possibility is less.

- No intermixing of shell side and tube side fluid.

- No limitation on a number of tube side passes.

- Since straight tubes are used, tube replacement is easier.

- Tubes can be cleaned mechanically or chemically.

- Minimum bypassing of shell-side fluid between the tube bundle and shell.

Disadvantages :

- It is not possible to remove the tube bundle for inspection and cleaning.

- The outer surface of the tube cannot be cleaned manually or mechanically.

- Shell and tube sheet material should be weldable together.

No comments